Shorten the sugar penetration time and enhance the taste. OrangeMech is a high-quality Vacuum Sugar-Soaking Machine specially designed for fruit products.

Product advantages

High productivity

Vacuum Sugar Impregnation Machine has a high degree of automation, and the sugar infiltration cycle is short, and the production efficiency is significantly improved.

High quality

Vacuum Sugar-Soaking Machine can ensure the uniform penetration of sugar into materials, with uniform flavor and good quality, and the design of sugar penetration process is stable.

Anti-corrosion and durability

Vacuum Sugar Dipping Pot Machine adopts heavy-duty industrial-grade durable design, which supports continuous and uninterrupted operation.

Product parameter

| Inner diameter/depth of sugar soaking machine | Φ800mm / 600mm |

| Capacity | 100-150kg/pot |

| Heating power of sugar pot | 24kw |

| Sugar cooking pot power | 1.5kw |

| Vacuum pump power | 4kw |

| Power voltage | 380V 50HZ customized |

| Total installed power | 54kw |

| Dimensions | 2500*1430*1550mm |

Control panel

Vacuum sugar dipping machine is easy to operate, and all parameters can be adjusted, which is convenient and fast.

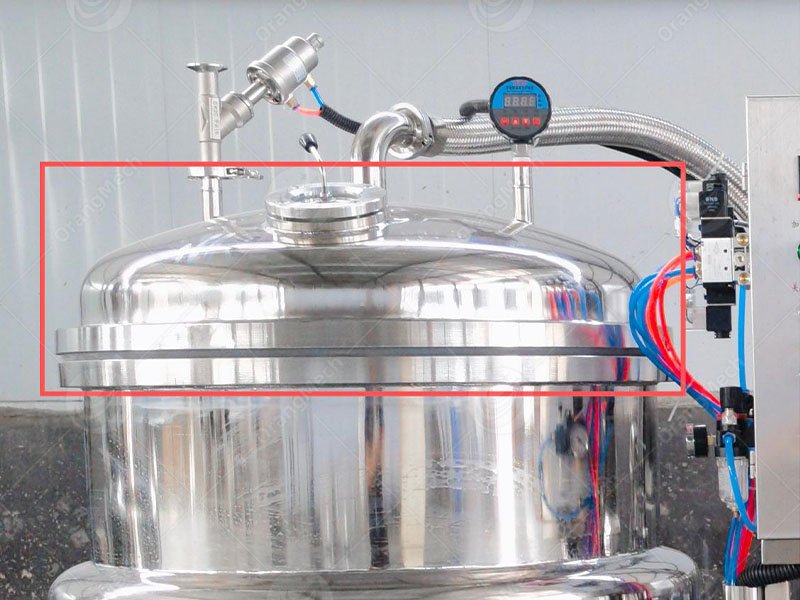

Thickened sealing ring

The vacuum sugar dipping cooking pot machine has enhanced sealing performance and effectively improved production efficiency.

Pressure controller

The pressure information is displayed in digital form with a reminder function to ensure the consistency of sugar drip effect.

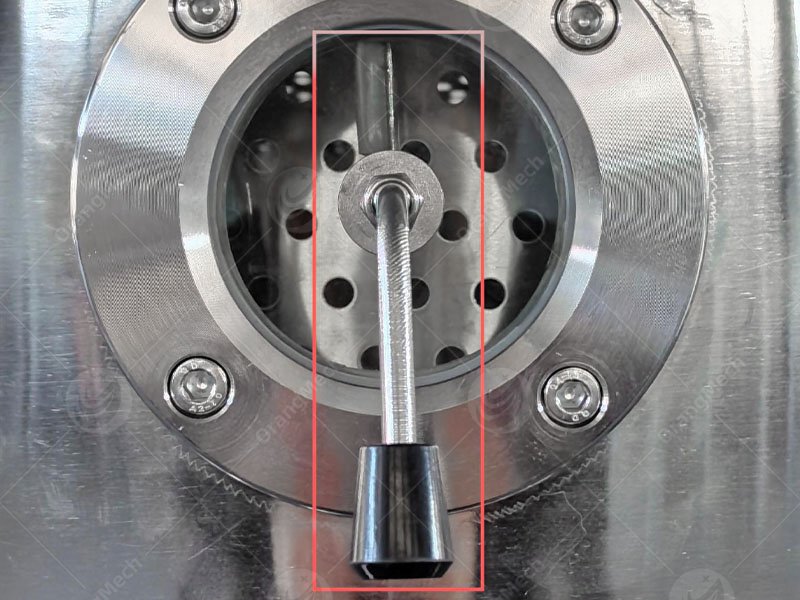

Observation hole

Using a scraper, it is convenient to observe the situation in the sugar immersion pot.

Material basket

Hollow design ensures that the material is completely immersed in sugar, which is convenient for loading and unloading of raw materials, clean and easy to operate.

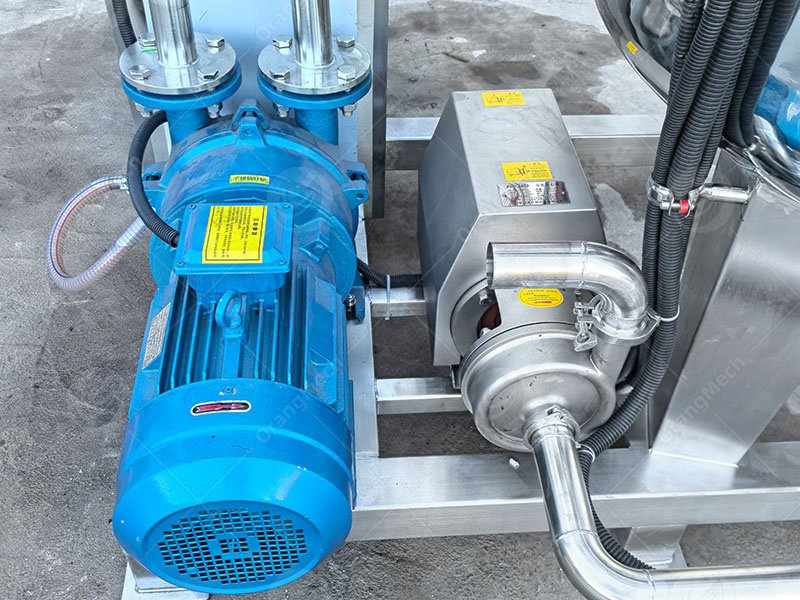

Sugar pump

The sugar solution can be recycled, which has the function of filtration and can also prevent the sugar solution from being polluted by external air.

Product application

◉ Large-scale food processing factory: it can meet the needs of continuous industrial processing and production.

◉ OEM/ODM OEM: Perfect to meet your customized sugar infiltration needs.

◉ Manufacturers of high-quality sugar products: there are requirements for high quality and consistent flavor of finished products, which can ensure.