Do you want to produce gummies in various shapes and formulations? OrangeMech candy manufacturing equipment offers reliable operation and flexible recipes!

Product advantages

Simple operation

PLC intelligent control system can directly and accurately control formula, pouring quantity and different shapes.

Save labor cost

gummy candy production line is equipped with the functions of continuous conveying and automatic demoulding, which greatly reduces labor cost.

Health and safety

the equipment is made of food-grade stainless steel, which conforms to international health standards and is a promise and guarantee for human health.

Improve production efficiency

the automatic gummy machine has high production capacity and speed, and can also ensure the uniform quality of soft candy and improve the overall production capacity.

Flexible customization

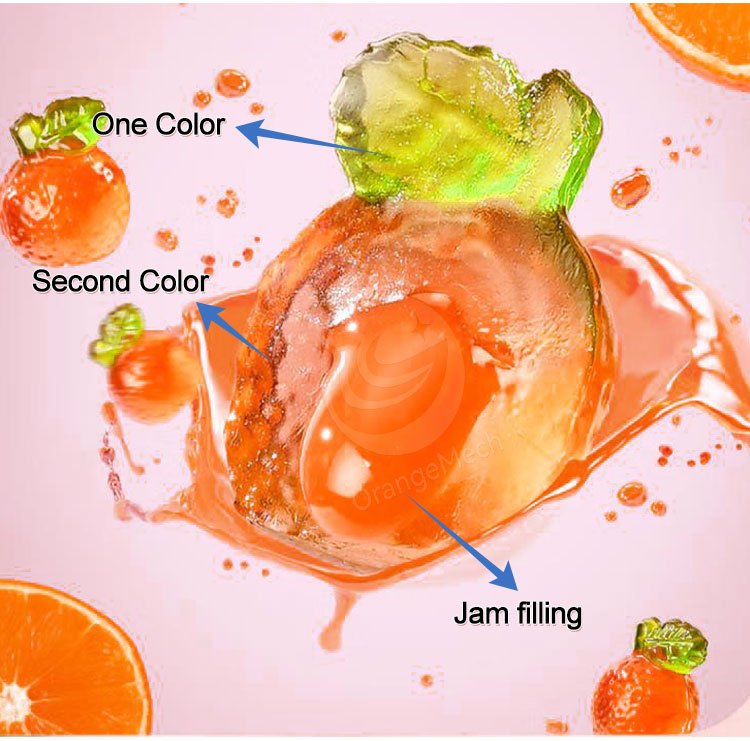

molds with different shapes can be customized, and all the popular soft candy balls in the market can be customized. The molds are easy to demould and clean, and various formulas can be flexibly configured.

Product parameter

| Model | OrangeMech -150 | OrangeMech -300 | OrangeMech -450 | OrangeMech -600 |

| standard production volume(kg/hour) | 150 | 300 | 450 | 600 |

| The sugar levels | 2-6g | 2-6g | 2-6g | 2-6g |

| pouring rate | 45-55n/min | 45-55n/min | 45-55n/min | 45-55n/min |

| Steam demand | 0.2m³/min, | 0.2m³/min, | 0.2m³/min, | 0.2m³/min |

| 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | |

| Work environment requirements | Temperature:20-25℃ | Temperature:20-25℃ | Temperature:20-25℃ | Temperature:20-25℃ |

| humidity :55% | humidity :55% | humidity :55% | humidity :55% | |

| Total Power | 18kw/380V | 27kw/380V | 34kw/380V | 38kw/380V |

| Overall length | 15m | 17m | 17m | 20m |

| Overall weight | 3500kg | 4000kg | 4500kg | 5000kg |

Melting pot

Gummy machine has good melting effect, high melting efficiency, long holding time and uniform heating, and is the basic equipment for forming gum.

Forming Machine

Gummie candy manufacturing equipment accurately controls quantitative pouring to achieve perfect molding effect.

Safety and health

The whole working environment of gummy candy production line is clean and tidy, which meets the production requirements of food hygiene.

PLC contorl

PLC man-machine control of automatic gummy machine: Simple operation and accurate setting.

Stainless steel material

Support customers to customize the mold with the required shape with patterns.

Stainless steel material

The main body of gummy production line machine and the part contacting with food are made of stainless steel, which is durable and corrosion-resistant.

Product application

◉ Gummy candy production lines are widely used in vitamin brand processing plants.

◉ Gummy candy and jelly food companies are innovating and upgrading their brands, making them ideal for chain stores and large markets.

◉ Large candy factories and OEM/ODM manufacturers can produce a variety of functional gummies, vitamin gummies, fruit gummies, gelatin gummies, and other products.