Orange Mech’s chocolate coating line feature precise coating, automatic temperature control, enhanced product quality and production efficiency!

Product advantages

Compact structure and stable performance

The chocolate coating machine takes up little space and is easy to install.The fuselage is made of 304 food-grade stainless steel, which meets the national food safety standards. If there is any abnormality, press the emergency stop button to stop immediately to ensure the safety of operators.

Easy to clean, safe and reliable

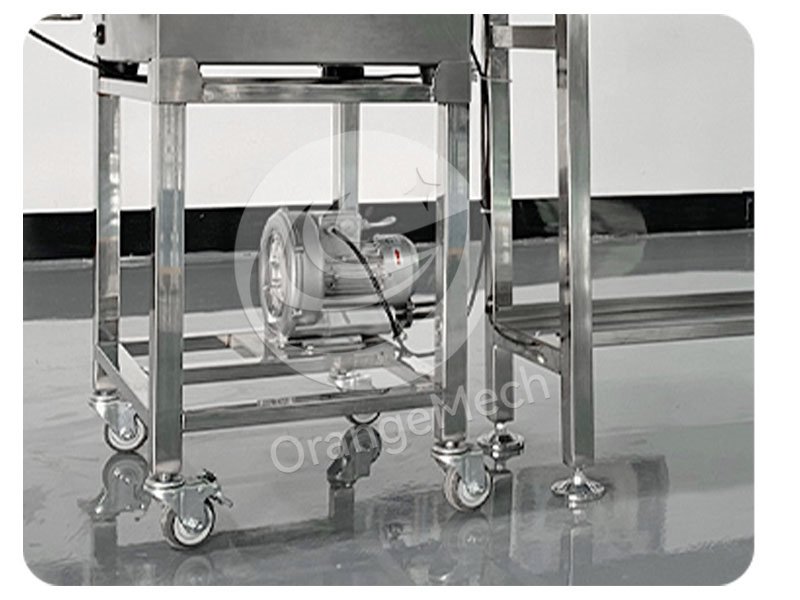

The whole machine is made of food-grade stainless steel with smooth surface and no dead angle, which is easy to clean and maintain. The coating area can be quickly disassembled and cleaned to avoid cross-contamination. The mobile design is equipped with universal wheels, which is convenient for equipment shifting and cleaning.

Wide range of applicable products

It can be applied to chocolate coating processing of biscuits, nuts, sweets, cakes and other products. Uniform coating can be achieved for both brittle biscuits and soft cakes. The equipment is especially suitable for small batch and multi-variety production requirements.

The temperature is accurate and controllable

Automatic chocolate coating machine use 1.4KW electric heating system, the heating speed is fast and the temperature control is accurate. Automatic constant temperature function ensures that chocolate always keeps the best working temperature, so as to avoid the coating quality being affected by temperature fluctuation.

saving raw materials

The outlet is equipped with an adjustable air knife system, and the air volume can be adjusted freely according to the product characteristics, which can effectively blow away excess chocolate on the product surface, and the recovery rate can reach over 90%. Unique slurry spraying design ensures uniform coating thickness.

Flexible adjustment

Conveyor belt is equipped with pressure wheel design to ensure smooth transition of products. The belt is elastic and adjustable to meet different production requirements. The control panel is designed with knob, which is intuitive and simple to operate and can be used without professionals.

Product parameter

| Parameter | Specification |

| Maximum Output | 2M/MIN |

| Heating Method | Electric Heating |

| Total Power | 1.4kw |

| Overall Dimension | 1997×570×1350MM |

| Key Features | Roasting Lamp, Blower, Stainless Steel Mobile Table |

304 Stainless Steel

The coating area is made of food-grade 304 stainless steel, which is hygienic, aesthetically pleasing, and easy to clean.

Redundant Simplified Design

The air knife device of the automatic chocolate coating machine can precisely blow away excess chocolate, with adjustable airflow and controllable coating thickness.

Automatic Tilting

During segmented transfer, even high-viscosity materials will not be carried away by the mesh belt. It also ensures stable operation of the conveyor belt.

Universal Wheels

The conveyor belt is equipped with pressure rollers to ensure smooth product transition and easy movement, saving time and effort.

Control Panel

The PLC control panel can be set to English, allowing for precise parameter control and simple operation.

Product application

1. Small food workshops:Orange Mech’s coating chocolate machine can complete cooling without complicated matching, and it is suitable for start-ups or small batch production with small investment and quick effect.

2. Large food processing plants:Orange Mech’s Chocolate Coating Machine can be connected with cooling tunnel to realize large-scale production, stable performance and efficient coating effect, which can greatly improve productivity and product consistency.

3. Bakery:Orange Mech’s coating chocolate machine can make chocolate coating for various desserts, attract more consumers and enhance the competitiveness of stores.